Our Story & Forest

The History

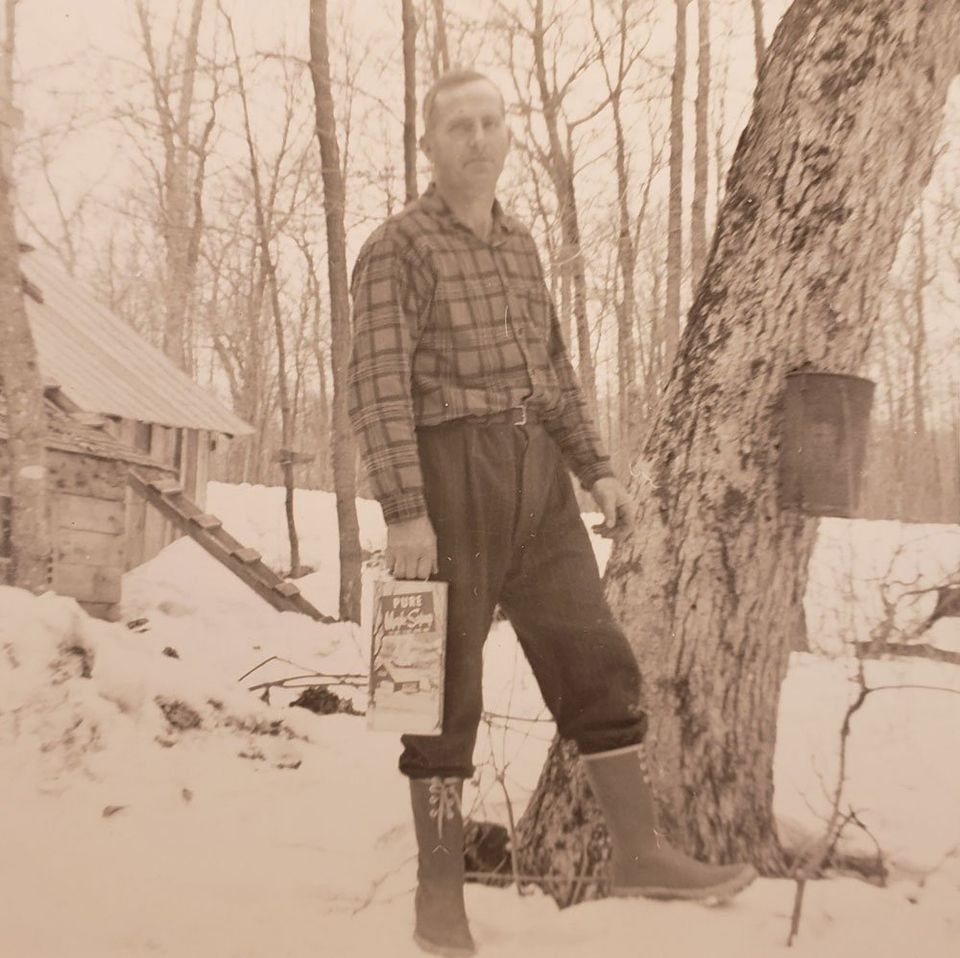

Bill’s Great Great Grandfather (William) was the first of four brothers to immigrate to Canada from England in 1851. He moved north, census records showing him as a farmer in Oro Township in 1861. This would have been the start of Hubbert’s making syrup in Canada! His Great Grandfather (William) farmed in Innisfil Township before moving to Manitoulin island where he produced syrup as part of a mixed farm. This is where his son Frank and grandson Harold were raised. Bill’s Father (Harold) established the Hubbert farm in Strong Township in 1949 which is where we make our maple syrup today.

Harold and his wife Alice purchased 200 acres in Strong township east of the village of Sundridge in 1948 as part of the Veteran Lands Act designed to settle returning World War 2 veterans on farms. The first maple crop for them was in the spring of 1949. All sap from close to 2,000 trees was collected by horse and sleigh and the syrup was produced in a sugarhouse deep in the woodlot. Over time other aspects of the farm were given up to concentrate exclusively on maple including the addition of an adjacent 100 acre woodlot.

Working side by side with his parents, Bill and his partner Lori took over operations of the farm while working full time. Bill and Lori purchased the farm from his parents and eventually added to the woodlot by purchasing three adjacent farms. Both have a degree in Forestry and endeavour to use best practices for managing the woodlot on the property. Bill spent 34 years working as a Registered Professional Forester in Algonquin Park where much of the science used in managing maple dominated forests in Ontario was developed.

We actively manage the woodlot by thinning out defective material and leaving the best trees to improve the quality of the forest over time. This area is close to the northern limit of the range of sugar maple in North America and so presents its own unique challenges in promoting and maintaining a healthy forest.

The Sugarbush covers approximately 400 acres and has another 400 acres of mixed forest to go along with a variety of lakes, ponds and old fields bringing the farm to 930 acres. Any open areas are assessed for potential for other future farm uses while providing habitat for wildlife.

Bill and Lori’s daughter Sarah along with her partner Xaver are the sixth generation of syrup maker and are working side by side to help with operations. Maple sap is collected at seven different locations around the farm and then transferred to our sugarhouse via pumps. The network of tubing stretching from tree to tree is in excess of 150 kilometres. The whole system is under a vacuum system to ensure freshness of the sap as it travels rapidly from each tree to the sugarhouse.

At the sugarhouse all sap is stored in a cool basement area to ensure maximum freshness. Sap is concentrated via a process called Reverse Osmosis prior to being boiled in a custom designed steam evaporator. All of the equipment used is stainless/food grade and in many cases items were designed by Bill and custom made for our unique situation.

Maple syrup is then packaged for sale or stored in Stainless steel barrels for bottling later. Filters and bottling equipment is operated year round to ensure we have a supply of best quality syrup for our many customers and retail partners. The maple crop is a variable one with many factors coming in to play in determining the volume of maple syrup produced. Our 18,000 taps can produce anywhere form 9,000 to 20,000 litres of finished maple syrup. Our goal is to make sure we can produce the best syrup possible and we have invested substantially in our sugarhouse and associated equipment with that goal.

We have been able to work with equipment manufacturers to customize items allowing us to keep quality as the focus while still operating efficiently. We belong to the Ontario Maple Syrup Producers Association (OMSPA) and frequently take part in work shops, information days and annual tours put on by the organization. This allows us to continue to learn and always have the most current information regarding regulation changes, standards and news for the maple industry.